High power LED controllers

TR-HT Series LED Controllers

Key features:

- 2 channel high resolution output

- 5A continuous mode, 50A pulse mode

- 150W per channel, 300W per unit

- Resolution from 0.6mA to 15mA

- GigE Vision compliant

- Operates with both TrinitiTM and non-TrinitiTM lights

The Gardasoft TR-HT series are industry’s highest power controllers for Machine Vision LED lighting; at 150W per channel, they are the perfect partner for driving high power LED Area and LED Bar lights.

LED drive performance

Highest power output

The Gardasoft TR-HT series provide the highest drive power for machine vision LED lighting. With unique switching technology, these controllers have 2 independent output channels, each rated at 150W and each capable of driving 50A in pulsed mode and 5A in continuous mode. Dual range output current with the design of the TR-HT controllers enables fine tuning at low currents – with resolution from 0.6mA to 15mA.

Voltage step-up

SafePowerTM removes the restriction of the output voltage needing to be less than the input voltage, and automatically steps up or down the voltage needed to drive or overdrive the lighting, up to a limit of 72V. SafePower works automatically without needing any configuration or user input. For example, the TR-HT range can use a 24VDC supply, regardless of the lighting connected.

In addition, PP mode allows the advantages of SafePower with the advantages of a direct current drive (as on the PP range of controllers). The output voltage to the lighting can be higher than the supply voltage, but without the limitations on pulse frequency that the RT controllers have.

Control of machine vision lighting

Modes of operation

Four modes of operation are provided separately for each channel of the TR-HT controllers enabling flexible operation:

| Continuous: |

Output is a continuous level |

| Pulse: |

Output is pulsed once per trigger |

| Switched: |

Output is switched by a digital input |

| Selected: |

Output intensity selected by a digital input |

Extra LED brightness

Patented SafeSenseTM technology creates a safe working environment for overdriving LED lights. Driving LEDs with a constant current source allows very precise overdriving. SafeSense ensures that the pulse width and duty cycle are kept within safe working limits. The end result is that much more light is gained from the LED lighting for your machine vision application.

This is in addition to the Triniti functionality which comes as standard with all TR-HT controllers and is applicable to Triniti-enabled lighting from manufacturers such as CCS, Smart Vision Lights, TPL and Metaphase.

Controllable digital I/O built-in

All TR-HT controllers have two built-in digital inputs for trigger control, and four digital output points with the ability to trigger external components such as cameras and reject gates.

Software and configuration

Triniti as standard (GigE Vision integration)

TR-HT Series controllers are GigE Vision compliant and are part of the Gardasoft Triniti machine vision platform; this enables expert control, operational intelligence and full integration of machine vision lighting - within a ‘plug and play’ environment.

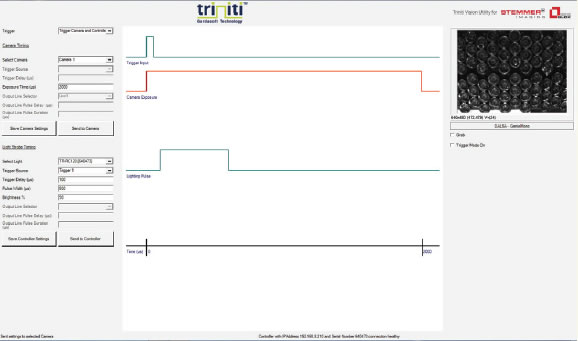

Vision timing utilities

Triniti application utilities are available for many of the leading image processing software packages such as Cognex VisionPro, National Instruments LabVIEW, Teledyne Dalsa Sherlock and Stemmer Imaging CVB.

Triniti SDK

For OEM implementations, applications can be written in any .NET language, including C#, VB and C++, giving full access to all Triniti light and control data.

Configuration options

All TR-HT controllers have options to be configured via 100base-T Ethernet or RS232. With the Ethernet options, a Web browser can be used to access the TH-HT controllers’ internal web pages allowing status to be viewed and parameters to be changed.

The TR-HT Series can also be configured using simple string commands sent from within their application program using RS232, TCP/IP or UDP, and the Triniti SDK (which is a free download from the Gardasoft website). The configuration is stored in non-volatile memory providing turnkey operation.

TR-HT High power LED Controller specification

| Specifications |

| Parameter | TR-HT220 | TR-HT260 |

| User interface | Ethernet | RS232 |

| Output channels | Two independent precision constant current outputs |

| Output channels (continuous) | 5A max per channel (within 150W envelope) |

| Output current (pulsed) | 50A max per channel (within 150W envelope)

In steps of 1mA for currents ≤2A

In steps of 15mA for currents >2A |

| Output power | 150W max average power per channel, 300W max total |

| Trigger input | Opto-isolated digital inputs. Logic HI = 3V min, 24V max |

| Trigger Delay (td) | 3µs to 5seconds |

| Pulse Width (PW)1 | 1µs to 5seconds |

| Minimum Step Change (PW+td≤500µs)2 | 0.1 µs typ |

| Minimum Step Change (500µs<PW+td≤100ms)2 | 5.0 µs typ |

| Minimum Step Change (100ms<PW+td≤10s)2 | 100 µs typ |

| Trigger rate | 15kHz max |

| Output voltage | 60V max per channel |

| Triniti interface | Gardasoft 4-wire Triniti lighting interface |

| Triniti communications interface | GigE Vision V2.0, GenICam, UDP/TCP, Third party protocols |

| Supply voltage, full output power | 21.6 to 52.8 VDC |

| Supply voltage, limited output power3 | 10.8 to 21.6 VDC |

| Dimensions | 256x140x61 mm |

| Weight | 1.3kg |

| Mounting | 6 off M4 clearance holes on integral mounting flanges. Fix TR-HT to heatsinking surface. |

| Operating temperature | +5 to +40°C |

| Humidity | 95% non-condensing |

| Standards | CE, RoHS2, REACH |

- Reduced output power for long pulse widths.

- This is the minimum incremental adjustment that may be applied to pulse width or trigger delay settings.

- Maximum power output (lighting power) is de-rated linearly in this supply voltage range with 50% output power at 10.8V to full power at 21.6V.