Remote diagnostics and logging of lighting data

Within the Gardasoft Triniti Intelligent Lighting system, all lights are now visible on the GigE Vision network. Seamless access is enabled to light settings and operation data.

- Remote setting of light parameters such as Intensity

- Access to operating history of light such as run-time

- Preventive maintenance notifications automatically sent by lights

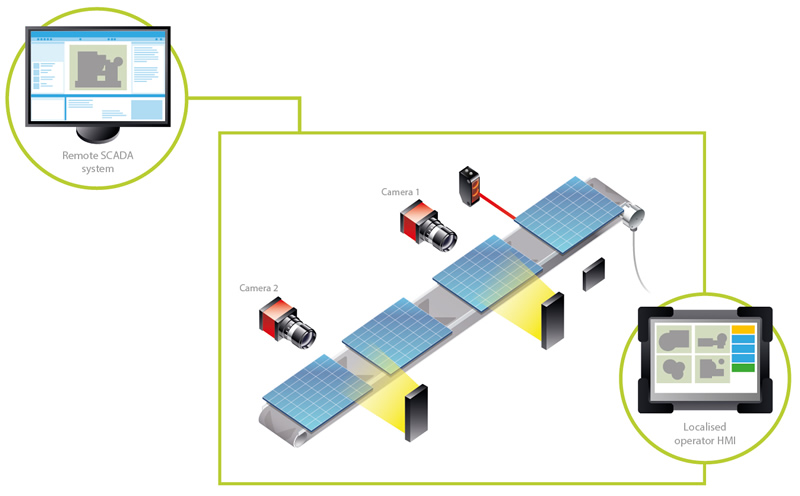

A typical user configuration is illustrated below where there is both a localised interface to the inspection system in addition to a remote reporting and logging to an overseeing SCADA system. Localised data would include functionality such as fine adjustment of lighting via an HMI, for example because a new product variation had been added within the manufacturing process. Another reason might be that the inspection process was experiencing too many rejects of healthy products because the image quality needed to be adjusted and improved.

Remote storage and analysis of lighting data for historical performance measurement and input to preventive maintenance

Localised lighting data for real-time performance monitoring and easy set-up for new products or product variances

The remote SCADA system would typically be logging historical light setting, especially related to the quantity of rejects, and date/time stamps of any changes (this latter point is especially important for legislative controlled applications within Pharmaceutical and Food sectors for example). The SCADA system would also receive alerts from the lighting for issues such as end of life or downtime – and these can be fed into repair and predictive maintenance programs for the related machine.