Achieving the best Machine Vision images

The starting point for achieving the best Machine Vision images begins with the best lighting and lighting control.

- A Camera can only capture what it can see

- Image processing software can only work with the image it receives from the camera

- The visibility of the target object(s) is a fundamental starting point

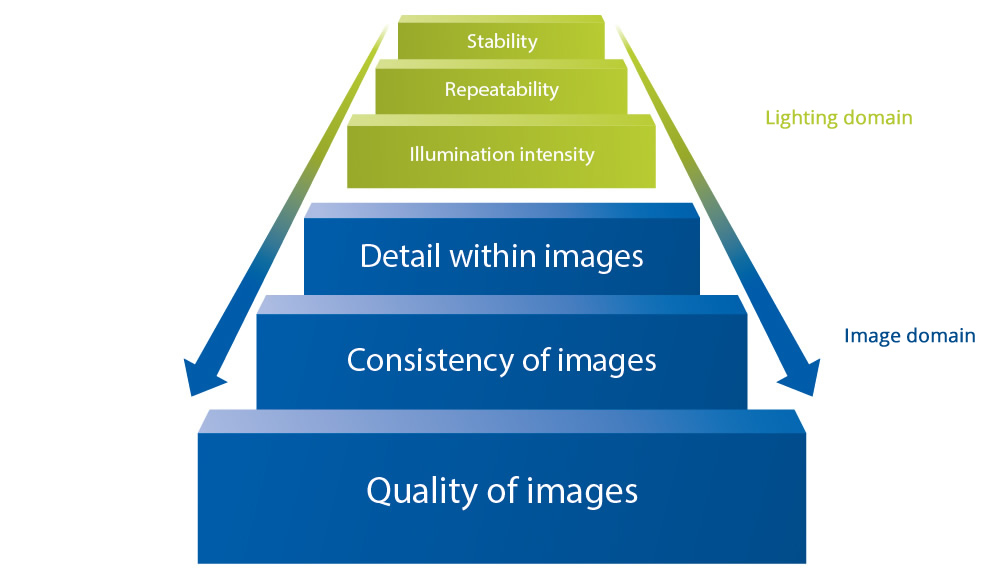

Machine Vision systems offer sophisticated engineering functionality - from state of the art camera technology through to high speed frame-grabbers and Image Processing software. A fundamental foundation for how successful and effective these systems can be is the visibility of the target object to be inspected, and especially the specific objectives for an inspection (for example missing parts, colour differentiation, blemishes, character recognition or sizing); and the starting point for the quality of these source images is the suitability and effectiveness of the lighting.

The illustration above indicates the importance of lighting factors such as stability and repeatability before even the more obvious lighting criteria such as wavelength, form factor and intensity - for a Machine Vision to perform consistently, the primary images must be consistent and so undefinable variations in lighting are unacceptable. See the section from Gardasoft on the importance of the correct light supply and control.

In reference to Triniti lighting, simple pulsing and control of lighting is enabled, and this can have a dramatic impact on the inspected image. In the example below, the first image on the left is with an object being illuminated with a continuous CCS Triniti light (model LDL2). For some applications these may be fine, however for others it may be necessary to see more detail such as the clarity of the indented character code on this object. Simply applying pulsing and overdriving to the same object with the same light creates quite different results.

In this example, the user could choose between image 2 and 3; note that there is additional benefit to the user in that the life-time of the light is extended because it is only pulsed when the object is present and not continuously as with image 1.

Image with Constant lighting

Image with same light, but 200% overdrive, 10ms pulses

Image with same light, but 400% overdrive, 5ms pulses